3 Steps to Maximizing the Effectiveness of Work Gloves

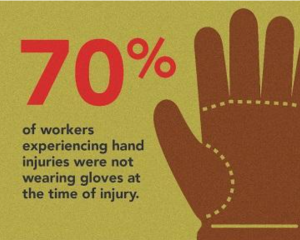

Did you know there were more than 1.1 million hand injuries in 2014? The U.S. Bureau of Labor Statistics (BLS) reports more than 70% of these injured workers were not wearing gloves at the time of injury. No wonder the Occupational Safety and Health Administration (OSHA) requires employers to provide hand protection when employee’s hands are exposed to hazards such as harmful chemicals, severe cuts or lacerations, abrasions, punctures, thermal burns and harmful temperature extremes. Equipping workers with gloves seems like a simple solution, but it involves several crucial steps.

Step 1: Assess Where Gloves Are Needed

A metal manufacturing client recently experienced an increasing number of hand lacerations in their manufacturing process. Reviewing loss experience like this is one way to assess where the right pair of gloves could reduce injuries. Another way is to conduct a job hazard analysis that considers the types of chemicals, machines and materials employees come in contact with and how gloves could reduce exposures to hazardous situations. The majority of gloves used to be designed for chemical exposures. Today, you’ll find gloves designed to protect workers from cuts, vibration, temperature extremes and more. EMC loss control professionals can help evaluate your loss experience and/or conduct a job hazard analysis to determine where gloves could help reduce the likelihood of hand injuries.

Step 2: Understand the Differences Between Gloves

The variety of potential occupational hand injuries makes selecting the right pair of gloves challenging. It’s essential that employees use gloves specifically designed for the hazards and tasks found in their workplace. Gloves designed for one hazard may not protect against a different hazard even though they appear to be an appropriate protective device. Of the workers who suffered injuries in the BLS study, 30% were not wearing the right type of glove for the job they were performing.

OSHA classifies gloves into the following categories:

- Leather Gloves—Protects against sparks, moderate heat, blows, chips and rough objects.

- Aluminized Gloves—Provides reflective and insulating protection against heat and requires an insert made of synthetic materials to protect against heat and cold.

- Aramid Fiber Gloves—Protects against heat and cold, are cut- and abrasive-resistant and wear well.

- Synthetic Gloves—Offers protection against heat and cold, are cut- and abrasive-resistant and may withstand some diluted acids. These materials do not stand up against alkalis and solvents.

- Fabric Gloves—Protects against dirt, slivers, chafing and abrasions. They do not provide sufficient protection against rough, sharp or heavy materials. Adding a plastic coating will strengthen some fabric gloves.

- Coated Fabric Gloves—Normally made from cotton flannel with napping on one side. By coating the unnapped side with plastic, fabric gloves are transformed into general purpose hand protection offering slip-resistant qualities. These gloves are used for tasks ranging from handling bricks and wire to chemical laboratory containers.

- Chemical-Resistant Gloves—Made with different kinds of rubber or plastic. As a general rule, the thicker the glove material, the greater the chemical resistance. However, thick gloves may impair grip and dexterity. When selecting gloves to protect against chemical exposure hazards, always check with the manufacturer or review the manufacturer’s product literature to determine the gloves’ effectiveness against specific workplace chemicals and conditions.

Most glove manufacturers provide online apps for determining the best glove for each situation. Your EMC loss control representative can also help determine which type of glove is best suited for the risks your employees face.

Step 3: Engage Your Workforce in Glove Selection and Maintenance

You may be responsible for purchasing gloves, but your workers have to wear them. We recommend including your workers in the process to make certain the gloves you purchase provide the level of comfort and dexterity they need. There are numerous styles of gloves within each category. Ask your glove supplier to provide several samples and allow workers to select the one that they feel will provide that essential balance between protection, comfort and dexterity.

Workers need to be trained on glove use and care to be effective. OSHA recommends gloves be inspected before each use to make certain they are not torn, punctured or made ineffective in any way. A visual inspection will help detect cuts or tears. A more thorough inspection of filling the gloves with water and tightly rolling the cuff toward the fingers will help reveal any pinhole leaks. Gloves that are discolored or stiff should not be used. Any gloves with impaired protective ability should be discarded and replaced. Chemical-resistant gloves should be evaluated with extra care, taking into consideration the toxicity of the chemicals involved and factors such as duration of exposure, storage and temperature.

Eliminate the Hazard When Possible

According to the hierarchy of hazard control, personal protective equipment such as gloves are considered the last resort in reducing workplace losses. Eliminating the hazard, substituting it with a less hazardous material, isolating people from the hazard or changing the way people work are always better alternatives. Whether it’s choosing the right glove or using the right loss control strategy, EMC loss control representatives are ready to help you protect your workers and their most valuable tool—their hands.

Info Gathered from EMC Insurance